API PLAN 23

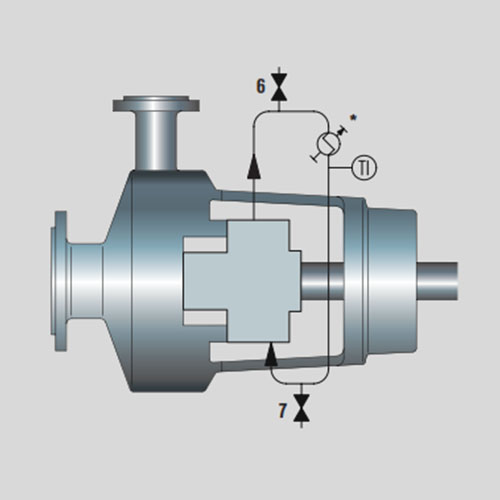

Recirculation from a circulation device in the seal chamber through a cooler and back into the seal chamber.

View Catalog

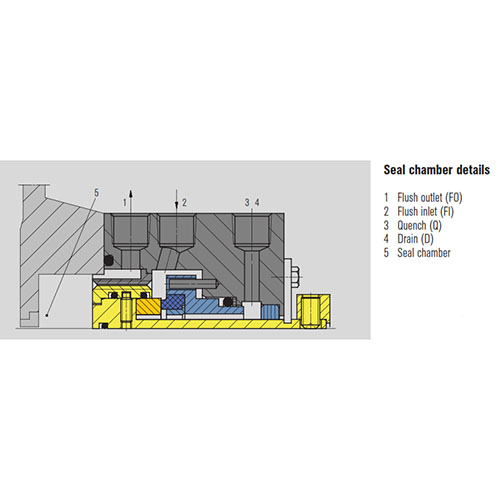

- Product in seal chamber is isolated from pumping area using a close clearance throat bushing.

- Increases product temperature margin in the seal chamber thus avoiding vaporization.

- Seal runs at a lower stabilized temperature of the media.

- Removes only the generated seal face heat and the heat soak from the pump area, thus the cooler is smaller and more effective as compared to an equivalent Plan 21.

- Uses a pumping ring for circulation in running condition.

- In idle condition, thermosiphon effect ensures circulation.

- A distributed flush is not recommended for this plan.

- For media with high viscosities and higher freezing points, steam must be used in the cooling lines instead of water.

- A high-point vent valve to be provided to vent the system before start-up.

- A close clearance throat bushing must always be in place to reduce the heat soak from the pump.

- Avoid sharp bends and 90° elbows in piping. Piping should be smooth and continuously rising.

- Cooler to be installed approx. 500 mm (20”) above pump centerline.

- Good quality cooling water is recommended to avoid deterioration of cooler efficiency.

- Flush outlet from seal chamber should be in the top half of the seal gland plate or the seal chamber.

- Hot hydrocarbons.

- Hot water services above 80 °C (176 °F).

- Boiler feed water.

- Applications where increasing seal chamber pressure to improve vapor pressure margin is not possible.